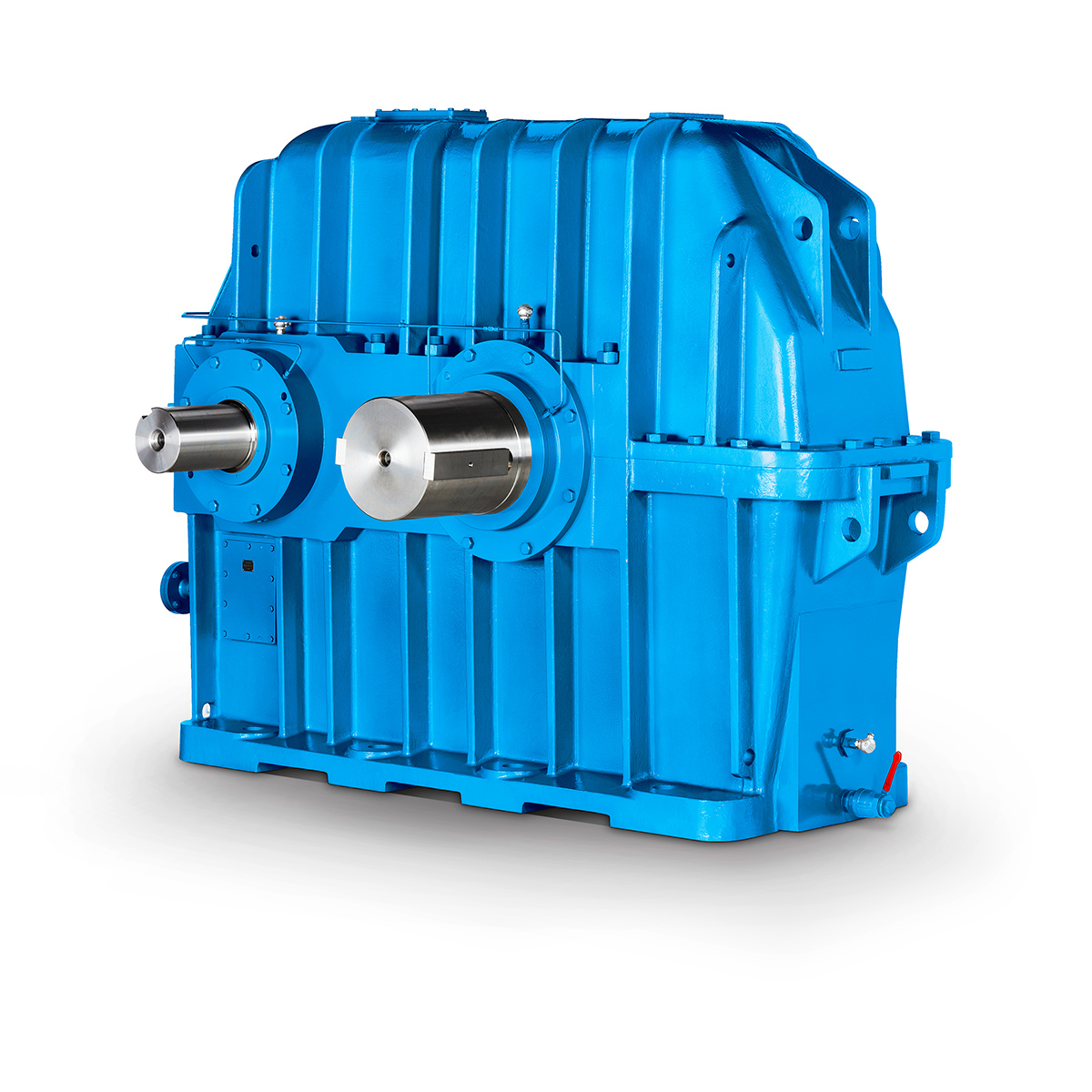

Single pinion drive

Flexible and Precise Gear Units for Optimum Tooth Mesh

Ball mills and rotary kilns are most challenging applications that demand a big deal from the drive system. High performance and reliability are very important. When it comes to milling of iron ore, limestone and clinker large axial and radial forces occur. Single-pinion drives must be able to withstand the acting forces permanently.

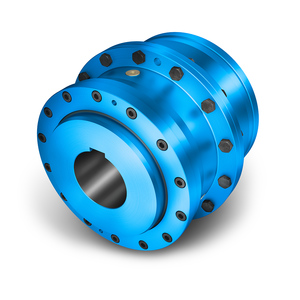

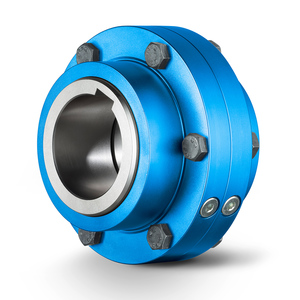

FLENDER MDSS is a standardized gear unit that was optimized to meet the high requirements of the application. For the girth gear/pinion drive, a FLENDER gear unit with input shaft on both sides from the standard range is generally used as the main gear unit. The main motor is connected to one side of the gear unit, while the auxiliary drive is connected to the other side. The pinion at the mill's girth gear can be connected via a double-jointed coupling with spacer to ensure the adjustability of the pinion. Single pinion drives are supplied in both fixed and self-aligning design. MDSS offer flexibility and precision for the optimum tooth mesh.

Your benefits at a glance

- Optimized gear teeth geometry

- High rigidity of housing

- High manufacturing quality

- Minimum noise generation

- Highest efficiency

Applications

- Crushing of minerals, ores, coal, or cement clinker in the building materials industry and raw materials preparation