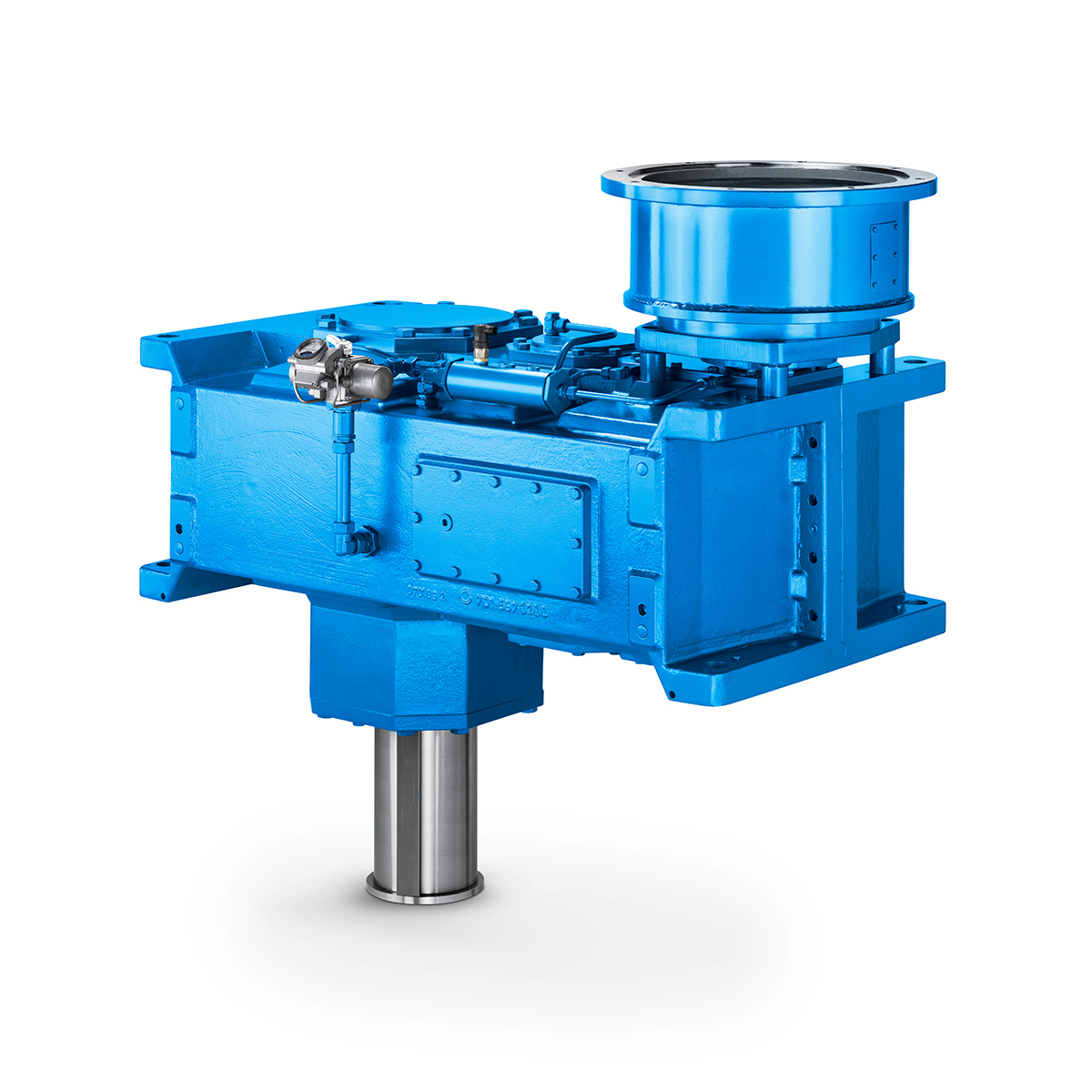

Aerator

| Rated Torque | 10.5 to 173 kNm |

| Transmission | i = 6.3 to 112 |

| Power | up to 3,600 kW |

| Translation Stages | 2- and 3-stage |

| Geartype | 16 |

| Mounting Position | vertical |

| Type | Helical and bevel helical gear units |

Strongly operating against biodegradable constituents

An aerator is an impeller in the biological part of a sewage treatment plant. It swirls the surface of the water so that it is enriched with oxygen. This activates the bacteria, so that the biodegradable constituents are removed from the sludge.

The impeller is fixed to the gear unit output shaft, which is extended vertically downward, a certain distance from the gear unit. To prevent the clarified water from becoming contaminated with gear oil, FLENDER gear units are designed with an output shaft featuring an oil retaining tube and a non-contacting, non-wearing shaft seal.

The axial and lateral loads resulting from the process are absorbed by extra-heavy-duty output shafts and output bearings.

Your benefits at a glance

- Oil pressure lubrication with flanged-on pump

- Reinforced bearings

- Dry well design (shaft seal is absolutely oil-tight)

- Coupling flange for mounting the aerator

- High operational reliability

- Low noise level

- High efficiencies

Applications

- Wastewater treatment