Crusher

FLENDER Crushers

Crushing Facts

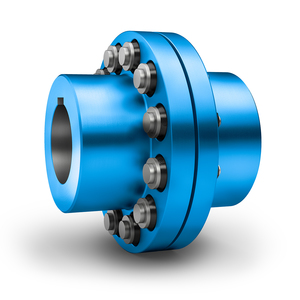

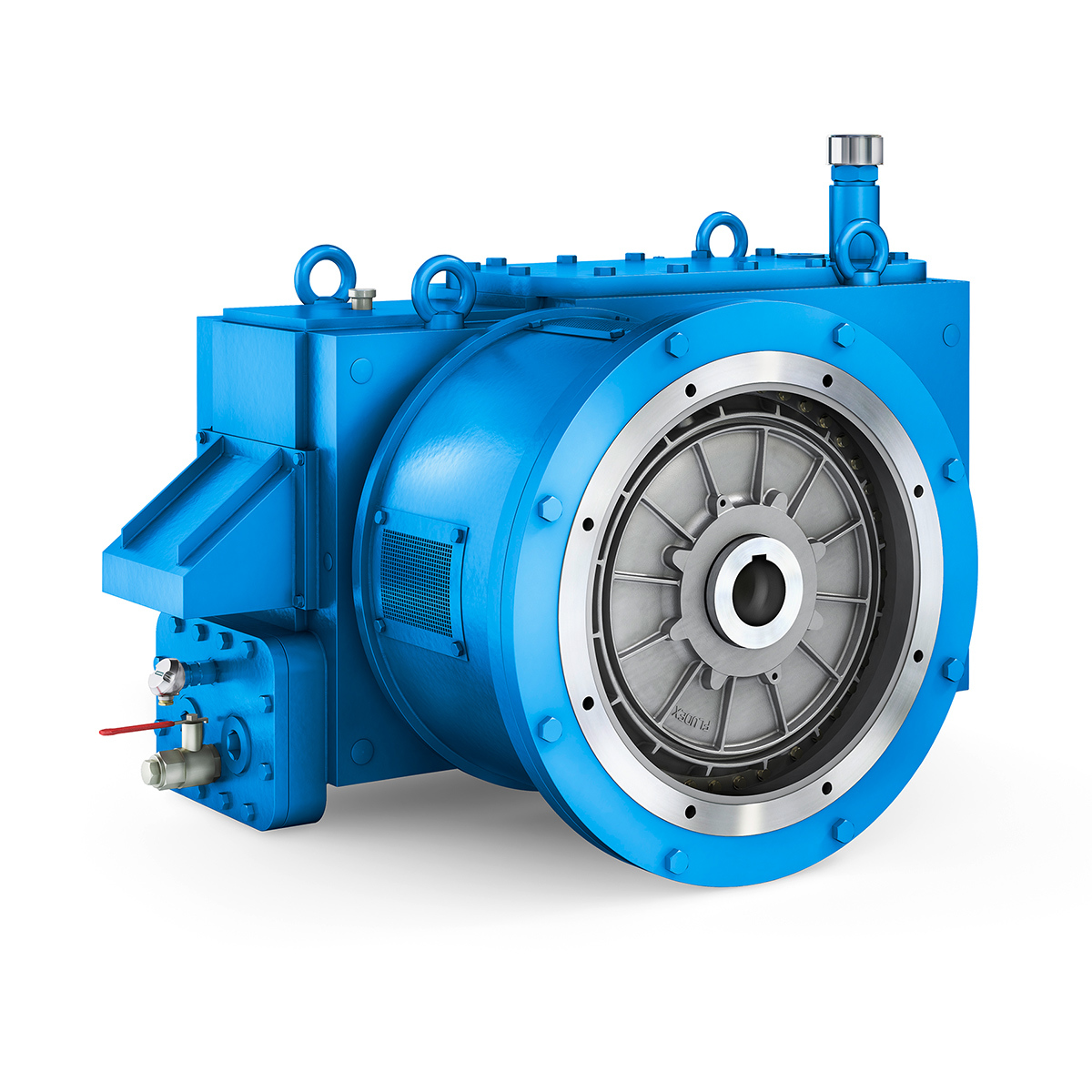

Based on our extensive experience, we provide you with perfectly tailored FLENDER drive solutions for a large variety of crusher types and configurations. The modular system of FLENDER gear units in helical and bevel-helical versions as well as planetary versions guarantees maximum individuality for your application. The huge variety of standard components, housing versions and mounting options enables the drive solution to be exactly designed to meet your specification and the special requirements of your application. This results in low costs and proven reliability as well as short delivery times.

As the center distance often plays a significant role, FLENDER offers several options for helical and bevel-helical gear units: Besides maintenance-friendly split housings, the product range also includes exceedingly rigid one-piece housings that are extremely compact and therefore ideal for confined installation spaces. The smaller rear dimension allows the gear units to be installed closer to each other. This not only creates a small center distance, but also simplifies the overall design of the crusher. We thus create flexibility, reduced engineering effort and shorter plant implementation times.

Profit from our extensive experience gained from numerous reference solutions and also from our interdisciplinary know-how that goes well beyond just the gear unit design itself – because with Flender Integrated Drive Systems, we always have a clear overview of the entire drive train.

Your benefits at a glance

- Robust, reliable and powerful

- Very compact and lightweight design

- Lockable for maintenance work

- Long service life and low life cycle costs

- Short delivery times, also via call-off orders

- Good price-performance ratio

Special product benefits

- Large degree of individuality from the standard product range

- Several housing versions

- Reduced rear dimension for small roller spacing

- Very large standard range of optional add-on components

- Shorter development processes and implementation times

- Bolt-on motor bell housing is maintenance-friendly

- Standardized wall mounting of the sizer gear units