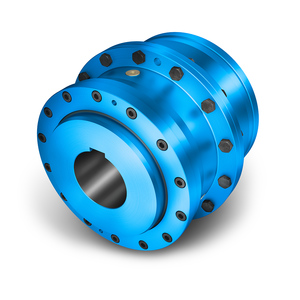

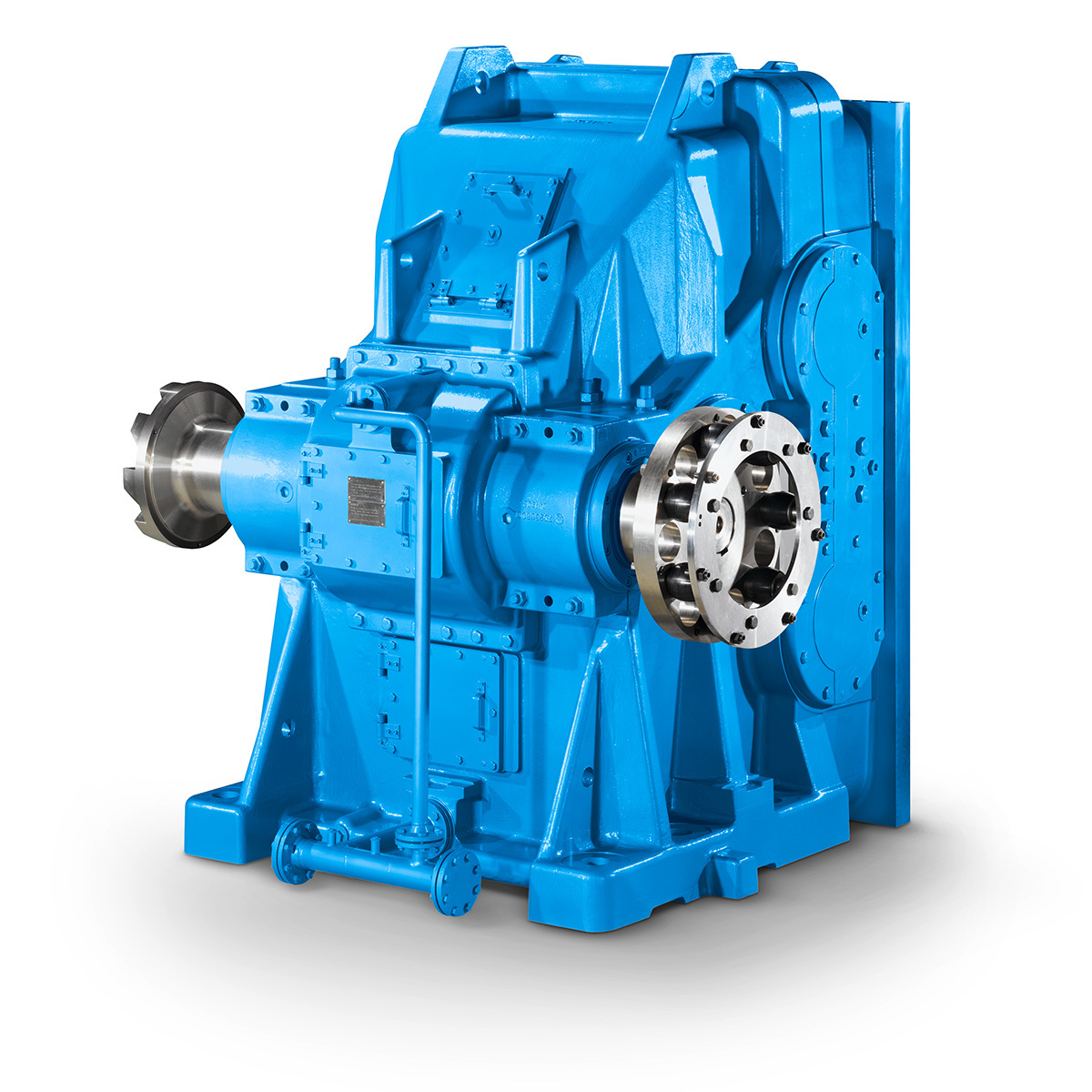

Girth gear units

Optimum contact pattern for the highest loads

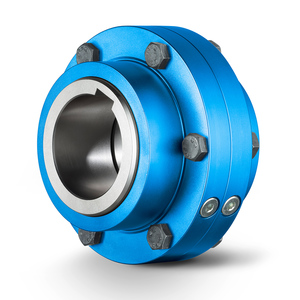

Particularly innovative are the direct meshing FLENDER girth gear units (DMG2). This gear unit type was developed for driving tube mills with girth gears. Here, the gear unit forms a single unit with the girth gear with which it meshes directly. Compared to the traditional pinion/girth gear variant with external pinion and girth gear, the system with the gear unit for the girth gear is by far more favorable. Tried and tested elements were brought together in an optimal combination. Fewer parts are required, and consequently the space requirements, and the installation and operating costs are reduced. The current generation of DMG2 gear units is available in four sizes. Consistent standardization results in a high availability of individual components. The DMG2 gear units cover the entire power range from 1,200 to 10,000 kW in stand-alone operation and up to 20,000 kW with the use of a dual drive. Worldwide, over 400 of these large gear units have already been deployed successfully.

Your benefits at a glance

- Compact and efficient drive

- More effective use of the girth gear

- Perfect load distribution across the entire girth gear width

Applications

- Crushing of minerals, ores, coal, or cement clinker in the building materials industry and coal preparation