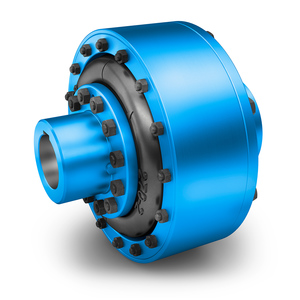

KMPS

Bestseller for optimized milling results

The reliability of each component as a crucial aspect of plant availability and the life cycle cost of drive equipment has a significant impact on the productivity of a cement production. Vertical Mill drives in the medium to high power range are used for the grinding of raw meal, clinker and slag. Flender offers by far the most comprehensive drive solutions for this challenging process. Our application-specific gear units for vertical mills offer high-quality design and manufacture, outstanding bearings, first-class gear tooth geometry and extraordinary housing stiffness, thus increasing service life and reducing life cycle costs. Flender can support customers with in-depth industry expertise, based on more than 50 years in the Cement Industry. Our gear units have been tried and tested hundreds of times.

The KMPS series is the optimum solution for power rates of up to 4000 kW.

Your benefits at a glance

- Optimized application-specific gear unit

- Comprehensive portfolio for vertical mills

- Extraordinary housing stiffness

- Optimized gear tooth geometry

- Wear free, fully hydrostatic pressure segment bearings

- Tried and tested concept with approx. 400 references

- global production concept

- international service locations

- wide variety of options

- maintenance-free tilting pad thrust bearings

Applications

- Grinding of raw material, clinker and slag