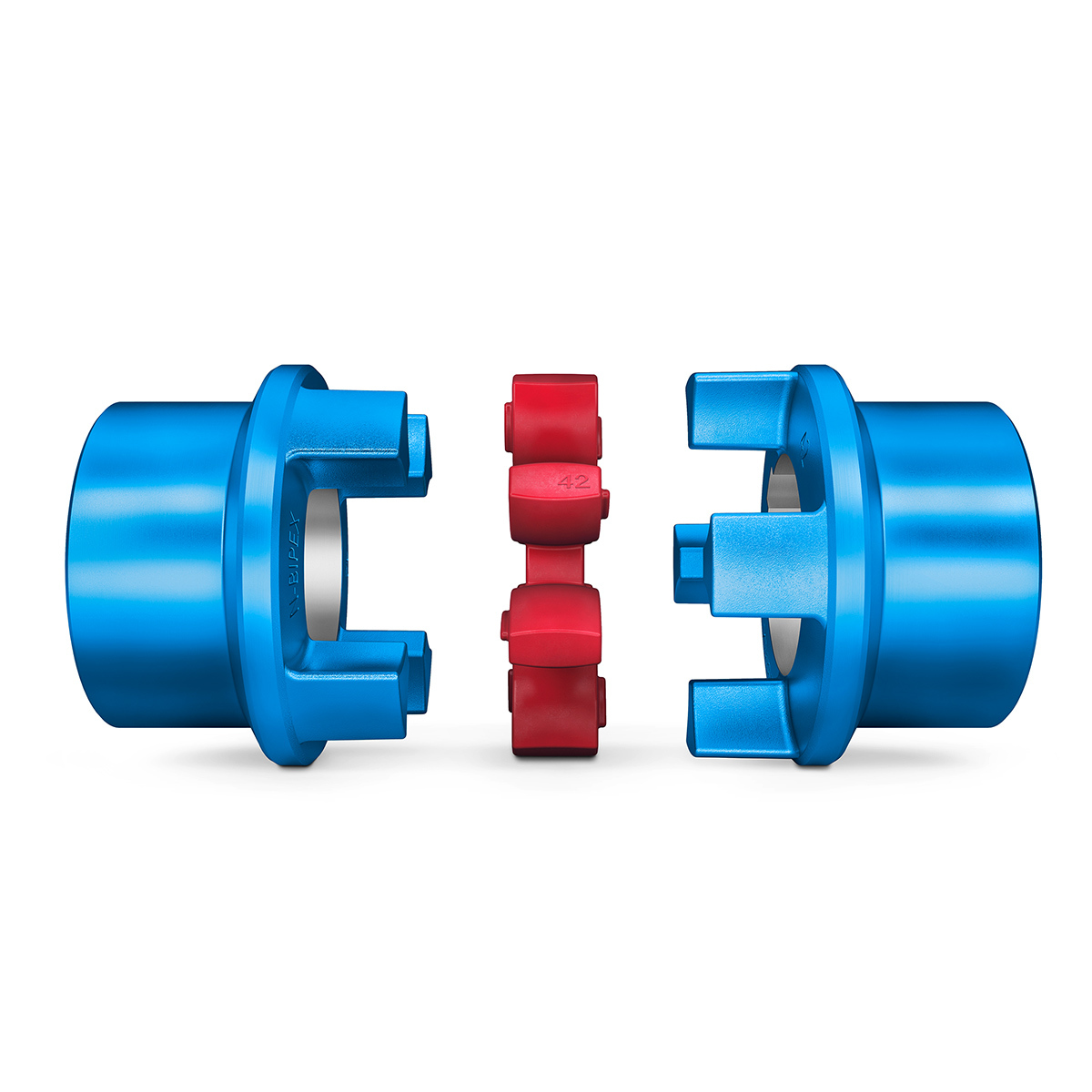

N-BIPEX Claw Coupling

The better choice of coupling for the process industry

- Damping shaft coupling that can be used universally to compensate for shaft misalignments

- Nominal torque range from TKN = 12 Nm up to 4,650 Nm with 10 sizes

- Temperature range: from – 50 °C to +100 °C

The coupling portfolios normally found on the market consist of comparable couplings with a maximum permissible torque corresponding to twice the coupling’s nominal torque. To be on the safe side – for example during the run-up phase of an asynchronous motor with typical starting torques and tilting moments – it is often necessary to fall back on the next-largest coupling size. If high rotational speeds or relatively large bores need to be taken into account, the market often offers costly steel solutions. The N-BIPEX® copes with just these situations and offers not only higher maximum torques but also an extended range of bores.

With its cast hubs, the N-BIPEX allows greater freedom when designing the cam geometry, thereby laying the foundation for the innovative curved design. Unlike the milled cams typically available on the market, this design results in uniform loading of the elastomer compression bodies under all conditions and, in particular, prevents inward deformation of the cam ring due to load peaks that can cause greater wear. Hubs made of high-quality nodular cast iron allow the N-BIPEX to cope with high rotational speeds and critical bores. All in all, the N-BIPEX provides reserves that are considerably greater than those normally available on the market, thus achieving a significant reduction in wear.

Your benefits at a glance

- High torque reserves (maximum torque = 3 × nominal torque) to effortlessly absorb torque peaks

- Reduced complexity and lower storage costs due to the use of a single hub to meet all requirements

- High-quality elastomers that ensure uniform load distribution and thus an optimal service life under all conditions

- Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)

- Available with taper clamping bush

Made in Germany, worldwide in use

- Mining and Cement: separators, heating technology

- Steel Production: shears, straightening machines

- Oil and gas: pumps, fans, compressors, air condensers

- Power Generation: pumps, fans, compressors, air condensers, water turbines

- Chemicals and Pharmaceuticals: driers, lauter tuns, pumps, fans, compressors, mixers, agitators, reactors

- Pulp and Paper: wastewater purification plants

- Water and Wastewater: aerators, water screw pumps

- Food and Beverage: lauter tuns, reactors, agitators, mixers

- Railway Vehicles: railway couplings

Did you know?

The extremely high-performance cam ring materials are available ex stock in three different Shore hardnesses with the following colors:

- 92 Shore A – red

- 95 Shore A – green

- 64 Shore D – blue